In the rapidly evolving world of technology, 3D printing stands out as a beacon of innovation, transforming industries from manufacturing to medicine. At the heart of this revolution are the materials that fuel the creation of objects layer by layer, offering a glimpse into a future where the only limit to production is imagination. As we look forward, the horizon is bright with the promise of new materials that will expand the capabilities of 3D printing even further.

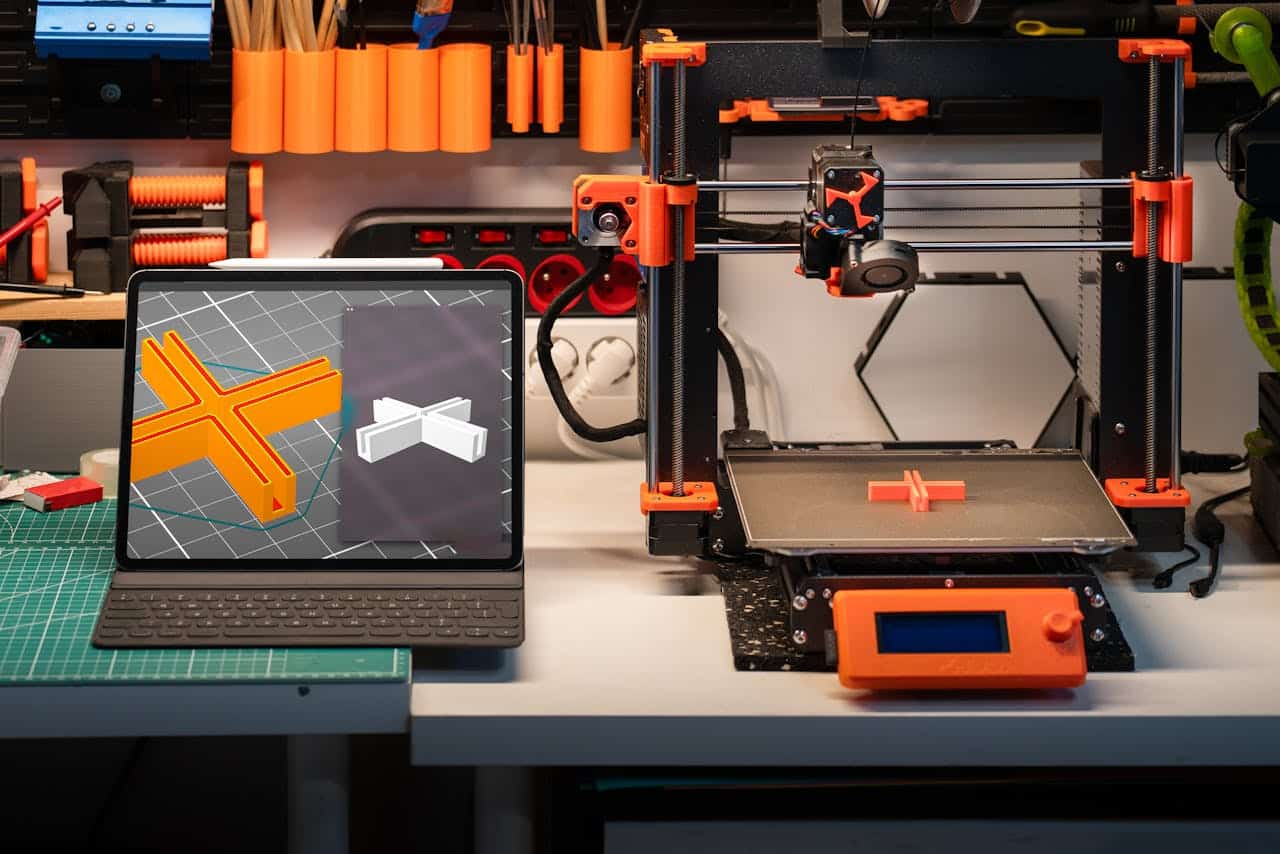

IMAGE: PEXELS

In this blog post, we delve into the advancements and future possibilities in 3D printing materials, highlighting the role of ABS filament and exploring the innovations poised to redefine what’s possible.

The Current State: ABS and Beyond

Acrylonitrile Butadiene Styrene (ABS) filament is a stalwart in the 3D printing industry, prized for its strength, flexibility, and high-temperature resistance. It’s the go-to material for applications requiring durability and precision, making it an indispensable part of the 3D printing arsenal. However, as we venture into the future, the industry is not content to rest on its laurels – the quest for materials that offer new properties and open up fresh applications is relentless.

Innovations on the Horizon

- Eco-friendly Materials: Sustainability is a pressing concern in all areas of technology, and 3D printing is no exception. Researchers are focusing on developing biodegradable and recycled materials that reduce environmental impact without compromising on quality. These eco-friendly alternatives promise to minimize waste and carbon footprint, making 3D printing a more sustainable choice for the future.

- Smart Materials: Imagine materials that can change color with temperature, conduct electricity, or heal themselves when damaged. Such smart materials are not far from becoming a reality in 3D printing. These innovations can revolutionize product design and functionality, offering dynamic possibilities that adapt to their environment or user input.

- Advanced Composites: The integration of composites in 3D printing is set to enhance the strength, stiffness, and thermal properties of printed objects. By combining materials such as carbon fiber, glass, or even metals with traditional 3D printing polymers, the resulting composites can achieve characteristics tailored to specific applications, from aerospace to automotive engineering.

- Metal and Ceramic Printing: While plastics dominate the 3D printing landscape, the future shines brightly for metal and ceramic printing. Advancements in printing technology are making it more accessible and cost-effective to print with these materials, opening up a world of possibilities for high-performance applications in industries where durability and high-temperature resistance are paramount.

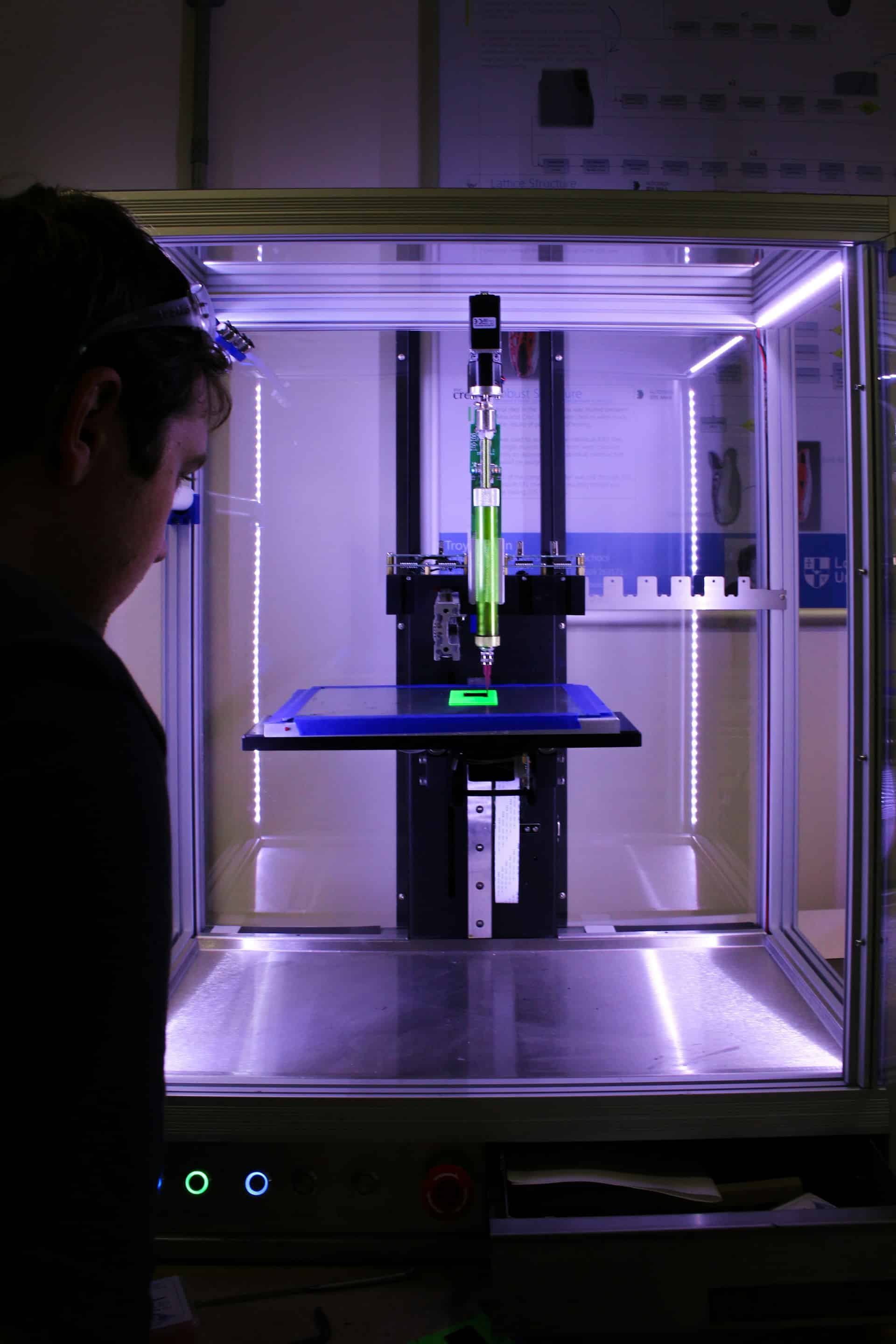

- Bioprinting: Perhaps one of the most exciting frontiers in 3D printing is bioprinting, where living cells are used as “ink” to create tissue and organs. This innovation has the potential to revolutionize medicine, offering solutions for organ transplants and tissue repair. As research progresses, the dream of printing fully functional organs is inching closer to reality.

The future of 3D printing materials is a landscape of unlimited potential, where the innovations on the horizon promise to redefine the boundaries of what’s possible

From sustainable alternatives to smart materials and from advanced composites to breakthroughs in bioprinting, the next generation of 3D printing materials will undoubtedly fuel a new era of creativity and innovation.

The role of ABS filament and other current materials as foundational elements will remain critical, serving as the building blocks upon which these future advancements will be built. As we look forward to these developments, one thing is clear: the future of 3D printing is bright, and it’s a future we can all look forward to with great anticipation.

IMAGE: UNSPLASH

If you are interested in even more technology-related articles and information from us here at Notilizer, then we have a lot to choose from.

COMMENTS